Asia remains the backbone of global supply chains in 2025, but sourcing in Asia is no longer as simple as picking the lowest-cost country. Rising wages in China, new manufacturing powerhouses in Southeast Asia, and shifting trade policies are reshaping the sourcing landscape.

For procurement and supply chain professionals, the key is to craft a strategic Asia sourcing plan that balances cost efficiency, supply chain resilience, product quality, and market access. By leveraging the complementary strengths of China, Vietnam, India, and Cambodia, businesses of all sizes can build a robust sourcing strategy that thrives amid change.

This article explores five core pillars of a successful Asia sourcing strategy, cost and labor efficiency, diversification and risk management, manufacturing specialization, quality assurance and scalability, and infrastructure, policy incentives, and trade access, illustrating how each country can play a role in an optimized 2025 sourcing portfolio.

Cost and Labor Efficiency in Key Asian Markets

Cost competitiveness has traditionally driven Asian sourcing, and labor costs remain a critical factor in 2025. However, a nuanced view of labor cost versus productivity is essential for strategic decision-making. China, once the go-to for ultra-cheap manufacturing, has seen its labor costs climb sharply over the past decade.

As of 2020, China’s average manufacturing wage was around US$6.5 per hour, more than double Vietnam’s roughly US$3 per hour (source). By 2024, Shanghai’s minimum wage reached RMB 2,690 (~US$370) per month (source), reflecting a broader rise in Chinese wages that puts them mid-pack globally (source).

In contrast, Vietnam’s average factory worker earned about US$302 per month in 2024 (source), and Cambodia’s garment sector minimum wage is set at only US$204 per month for 2024 (source).

India boasts some of the lowest labor costs in Asia, with a national minimum daily wage around INR 178 (~US$2.1) (source), translating to well under US$100 per month in many regions.

What do these numbers mean for sourcing?

China is no longer the ultra-low-cost option for labor-intensive products.

Companies producing high-volume, low-margin goods (like basic apparel or simple consumer goods) are increasingly turning to Vietnam, India, or Cambodia, where wages are a fraction of China’s.

For example, footwear and apparel brands have shifted in recent years, Nike now sources about 50% of its footwear from Vietnam (source), capitalizing on Vietnam’s lower wages and skilled workforce. Cambodia, with over 700,000 workers in its garment and footwear factories (source), attracts brands focused on rock-bottom costs, despite its smaller scale.

India’s vast labor pool and low wage levels make it attractive for labor-intensive manufacturing as well, evidenced by its huge textiles and clothing industry and growing electronics assembly sector.

Labor efficiency is more than just wage rates.

China’s higher wages are offset by decades of experience and high productivity. A Chinese factory worker often produces more output per hour than a newly trained worker elsewhere, thanks to advanced automation, better training, and mature industrial processes.

This means the unit labor cost (wage per widget produced) can remain competitive in China for complex, high-volume manufacturing.

In Vietnam and India, productivity is improving, Vietnam’s labor productivity has been rising ~3.6% annually in recent years (source), but these countries still trail China in industrial efficiency for many sectors.

Labor, skills and education

Vietnam benefits from a young, well-educated workforce (it ranks second in Southeast Asia on PISA scores for workforce skills) (source).

India offers a mix of highly skilled English-speaking engineers and low-skilled laborers; this duality allows for both advanced manufacturing and simple assembly, but maintaining consistent training at scale can be challenging.

Cambodia’s workforce is youthful and eager but generally lower-skilled, requiring more on-the-job training and oversight to meet international quality expectations (source).

To maximize cost and labor efficiency in your Asia sourcing strategy, consider a blended approach: use lower-cost countries for labor-intensive processes and higher-efficiency countries for complex tasks. For instance, a company might source fabric and basic stitching from Cambodia (taking advantage of <$1/hour labor) and then do final, detailed assembly or quality-critical finishing in Vietnam or China, where workers have more technical experience.

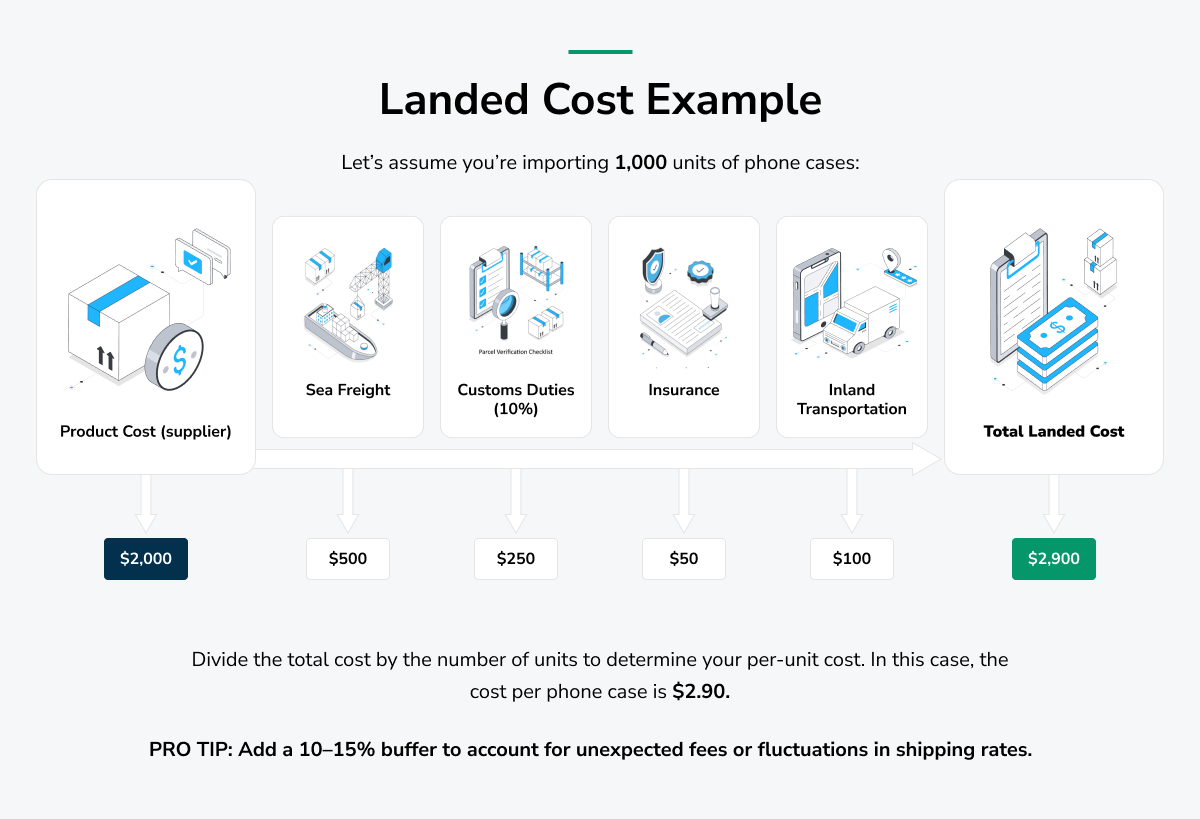

Total landed cost analysis is crucial, factor in wages, productivity, defect rates, and overtime needed to meet output targets. Often, the optimal solution is not choosing one country over another, but allocating each part of your production to the location that offers the best cost-performance ratio.

Actionable Tips – Managing Cost and Labor Efficiency:

Benchmark Wages vs. Productivity:

Don’t just chase the lowest wages. Compare how productivity and yield differ across suppliers. A higher-paid Chinese supplier might deliver lower cost per unit if they produce faster with fewer defects. In contrast, a Vietnamese or Indian supplier might excel in lower-skilled, high-labor content work.

Leverage “China+” for Labor:

Consider a “China+1” strategy where China handles complex manufacturing while a lower-cost country (Vietnam, India, or Cambodia) handles simpler, labor-intensive subassemblies or secondary product lines. This can yield immediate labor cost savings while maintaining quality for critical components.

Monitor Labor Trends:

Keep an eye on labor law changes and wage inflation. Vietnam and Cambodia routinely adjust minimum wages (Cambodia’s garment wages rose to $204 in 2024 (source)), and India’s states periodically revise rates. Ensure your cost models are updated and negotiate pricing accordingly.

Invest in Training:

In lower-cost countries, invest in worker training programs to boost efficiency. Governments often support vocational training (e.g. Vietnam’s government offers vocational education programs (source)). A sourcing partner like EWB can help coordinate on-site training or lean manufacturing projects to improve supplier productivity.

Diversification and Supply Chain Risk Management

If the past few years have taught businesses anything, over-reliance on a single country is a risky proposition. Trade wars, pandemics, geopolitical tensions, and natural disasters have all caused massive disruptions.

In 2025, supply chain diversification is not just a buzzword but a strategic imperative. Companies that once sourced 80–100% of products from China (“factory of the world”) are actively adopting a multi-country sourcing strategy to mitigate risks and improve resilience (source) (source).

China’s dominance is being challenged as companies implement the “China+1” (or +2 or +3) strategy. This means keeping a significant base in China (to leverage its scale and expertise) while developing additional sourcing hubs in countries like Vietnam, India, or Cambodia.

For example, Apple Inc. has dramatically diversified its manufacturing footprint: it began shifting some production out of China a few years ago and is now planning to produce 25% of all iPhones in India by 2025 (source), while Vietnam is slated to handle 20% of iPad and Apple Watch production and a whopping 65% of AirPods by 2025 (source) (source).

This “China+Vietnam+India” approach by a tech giant highlights how leveraging multiple countries can balance cost, capacity, and risk.

Similarly, Samsung, which has long manufactured in China, has built huge smartphone factories in Vietnam and India (one of Samsung’s largest phone plants globally is in Noida, India (source)) to serve different markets and hedge against disruptions. These moves ensure that production can continue elsewhere if one country faces a sudden shock (tariffs, lockdowns, political instability).

Supply chain risk management through diversification takes several forms:

Geographical diversification:

Spread manufacturing across different regions of Asia. For instance, a U.S. retailer might split its apparel line among China (for high-end, quick-turn fashion), Vietnam (for mid-range bulk orders), and Cambodia (for basic, cost-sensitive items). This way, a crisis in one country won’t halt all production.

In practice, many apparel brands now balance between China and Southeast Asia, China for its efficiency in complex garments and Southeast Asia for cheaper basics. Indeed, Western buyers have been steadily reducing China’s share in their sourcing portfolios; Q1 2025 data shows China’s portion of Western orders declining as buyers increase orders in other Asian countries (source) (source).

Supplier diversification:

Use multiple suppliers to avoid single points of failure even within one country. And crucially, dual-source critical components from two countries. For example, an electronics firm might source key chips from a supplier in China but have a second source in India or Vietnam. The alternate source can keep the supply flowing if a factory shutdown or export ban hits one supplier. This redundancy saved many companies during the pandemic and trade war volatility.

Market diversification and “China for China”:

Some companies choose to produce in multiple countries, not just for export but to serve local markets. India’s massive domestic market (1.4+ billion people) is a draw for this approach, and automakers and electronics firms manufacture in India to sell locally and regionally, reducing dependence on exports.

Meanwhile, China remains indispensable to many because of its market size and supplier base; rather than exit China entirely, firms are shifting export-oriented production out while still manufacturing in China for Chinese consumers (a “China for China” strategy). This balanced diversification ensures global sales aren’t all tied to one production base.

Diversifying does come with management complexity: juggling more suppliers, varying regulations, and logistics routes. But the payoff is resilience. Companies insulating themselves from shocks have fared better.

For instance, when U.S.–China tariffs hit, those who already had factories in Vietnam or India could pivot production and avoid punitive duties. Vietnam’s exports to the U.S. surged as companies rerouted orders away from tariff-laden China, highlighting the benefit of that ready alternative (source).

Similarly, if one country faces energy shortages or port delays, diversified supply chains can shift volume temporarily elsewhere.

Finally, don’t overlook “smaller” sourcing markets as part of your risk strategy. Cambodia, for example, has seen a 36% year-on-year increase in U.S. inspection and audit demand in early 2025 (source ), meaning U.S. brands are actively exploring it as a new sourcing base.

They may not move core production there, but by placing even a share of orders in Cambodia, they add an extra buffer against disruptions in Vietnam or China. The same goes for emerging hubs like Indonesia or the Philippines, each additional node in your supply chain network can reduce overall risk.

Actionable Tips – Diversifying and Mitigating Risk:

- Map Your Supply Chain Risk: Identify where you are over-concentrated (e.g. 90% of a product from one Chinese factory or city). Prioritize finding alternate suppliers for those high-risk areas. Even if the alternate is slightly higher cost, the risk reduction often justifies it.

- Adopt a “China+1 (or +N)” Plan: If you manufacture exclusively in China today, start by shifting 20-30% of production of select product lines to another country (Vietnam and India are common first choices). Pilot the dual production, iron out issues, and scale up the second source gradually. Ensure both sources meet your specs so they are interchangeable when needed.

- Stay Agile on Trade Policy: Geopolitics can change sourcing economics overnight. Tariff changes, trade agreements, or sanctions can suddenly make one country less viable. For example, new U.S. tariffs in 2025 are targeting not just China but also Vietnam and Cambodia (source ). Keep informed on trade policy and have contingency plans. If a new tariff hits Vietnam, perhaps shift volume to India or spread it among several ASEAN countries to dodge the impact.

- Leverage Sourcing Partners for Flexibility: Managing multiple countries is complex. Consider partnering with a sourcing firm (like EWB) that has on-ground teams in each country. They can quickly source alternatives, vet new suppliers, and handle local logistics when you need to pivot, acting as a “command center” for your diversified supply chain.

Manufacturing Specialization and Product Suitability

Each Asian manufacturing hub has developed specialized strengths. Aligning your product with the country best suited to make it is a cornerstone of an effective sourcing strategy, rather than a one-size-fits-all approach, smart sourcing in 2025 means matching product categories to the right country’s capabilities – and sometimes splitting product lines across countries to capitalize on each location’s expertise.

China:

Still the “manufacturing giant”, China has the most comprehensive industrial base in the world. It can produce virtually anything, from low-cost toys to advanced aerospace components. China excels in high-tech and precision manufacturing, accounting for about 26% of global high-tech exports (source), leading in electronics, machinery, medical devices, and more.

If you have complex electronics, appliances, or machinery, China’s ecosystem of specialized component suppliers and experienced factories is unparalleled. Need custom alloys, injection-mold tooling, or intricate PCB assemblies? China likely has multiple suppliers that can do it at scale.

Moreover, for products requiring speed and scale (e.g., launching a new consumer gadget worldwide), China’s capacity is unmatched – entire supply chain clusters are often located in one city, enabling fast turnarounds.

However, for simpler products or where cost is king, China may be “overkill” or too expensive today. Its strength in producing mass volumes efficiently (source) (source) means if you need millions of units quickly and reliably, China is probably the best bet, but you’ll pay somewhat higher labor and overhead costs for that robustness.

Vietnam:

Vietnam has risen as a manufacturing all-rounder with particular strengths in textiles/apparel, footwear, and consumer electronics assembly (source) (source). Major global brands produce in Vietnam: it’s a top source for apparel (fast-fashion giants like H&M, Zara, and sportswear makers like Nike and Adidas rely heavily on Vietnam (source)) and is now a crucial node in electronics (Samsung makes a significant share of its smartphones in Vietnam, and companies like LG, Nokia, and Intel have invested billions in Vietnamese production facilities (source)).

Vietnam is ideal for labor-intensive but moderately technical products: shoes, garments with detailed stitching, furniture (especially wooden furniture), basic electronics like phones, earbuds, and computer peripherals. It offers a balance of decent quality and reasonable cost. For example, Vietnam might not design the latest chip in electronics, but it can assemble smartphones or consumer devices to global quality standards, given the investment by tech firms.

One limitation is specialized or highly complex manufacturing – Vietnam is still catching up in areas like advanced automotive parts, semiconductor fabrication, or heavy industrial equipment (source). But even that is evolving: the north of Vietnam, near China’s border, is becoming a precision manufacturing hub for electronics and components, partly due to spillover knowledge from Chinese investors (source).

If your product is in a mature, high-volume category (apparel, electronics, home goods), Vietnam is likely a strong candidate offering a mix of quality and cost advantages. It’s often cited as the best “all-around alternative” for electronics and apparel when companies need to move away from China (source).

India:

India’s manufacturing profile is unique. It is famously strong in textiles and apparel (especially cotton goods), pharmaceuticals, automotive components, and increasingly electronics assembly (source) (source). India is sometimes called the “pharmacy of the world” – its pharmaceutical factories supply a large share of generic drugs globally, leveraging low costs and skilled chemists.

If you are sourcing pharmaceuticals, chemicals, or medical products, India is a top choice due to its expertise and large number of FDA-approved plants. In textiles, India offers everything from raw cotton and yarn to finished garments; it’s particularly known for home textiles (bedsheets, towels) and garments where fabric sourcing (like fine cotton) matters.

Automotive and engineering goods are another strength – Indian suppliers produce a wide range of auto parts, industrial castings, and machinery components, often with good craftsmanship at lower prices than Western or East Asian suppliers. For instance, many global automotive OEMs have trusted Indian component vendors for years.

India also has niche strengths:

Custom manufacturing and smaller batch production can be a good fit (source) (source) – a skilled network of smaller workshops and factories can produce bespoke items, handicrafts, or specialized equipment, tapping into India’s engineering and artisan talent. The country has also attracted big electronics investments under schemes like “Make in India” and the

Production-Linked Incentives: Thus, smartphone and electronics assembly are booming (Apple’s suppliers now assemble iPhones and soon AirPods in India, as noted, and Samsung runs large TV and phone plants).

One must note, however, India’s challenges:

Inconsistent quality in some industries, fragmented supply chains (you may need to import certain high-tech components due to gaps), and longer lead times for complex assembly. It’s excellent for cost and capable in many sectors, but often requires strong project management and supplier development to reach the quality and efficiency levels desired.

Cambodia:

Among the four, Cambodia is the new frontier, focused on basic manufacturing. Its industrial base revolves around garments, footwear, and travel goods – these make up roughly 60% of Cambodia’s export earnings (source) and employ the majority of its factory workers (source).

For companies in apparel, textiles, or light consumer goods looking for the absolute lowest costs, Cambodia is very attractive. It has abundant young labor, low wages, and tariff-free access to some big markets (historically the EU, under the Everything But Arms scheme, though the EU has partially withdrawn those benefits recently (source)).

Product suitability for Cambodia is typically goods that can tolerate a simpler manufacturing setup and don’t require advanced precision. Examples: basic T-shirts, uniforms, denim jeans, simple shoes, or basic assembly of goods like simple electronics or bicycles (Cambodia has also grown as an exporter of bicycles to the EU, taking advantage of trade preferences).

What Cambodia lacks is diversification and scale in advanced industries – you won’t find cutting-edge electronics or complex machinery production there. Many Cambodian factories are foreign-owned (often by Chinese, Thai, or Vietnamese firms) that use it as a low-cost satellite for labor-intensive processes while importing raw materials from abroad.

Thus, Cambodia is best used as a complement in your sourcing strategy, for the product categories where it excels or as a secondary source to supplement capacity during peak demand.

In summary, each country has a “sweet spot” in terms of product suitability. The savvy sourcing professional will allocate products accordingly:

- High-tech electronics, sophisticated machinery, large-scale production runs: China (primary) and increasingly Vietnam (for mid-tech assembly) are ideal. Example: Consumer electronics companies often manufacture critical high-value components in China, but do final assembly in Vietnam to save on labor and diversify risk (source) (source).

- Textiles, apparel, footwear: Vietnam and India for higher quality or complex items; Cambodia for basics and cost-critical orders; China for high-end technical textiles or when speed is crucial. Example: A fashion brand might source intricate, high-fashion apparel from China (ensuring top-notch finish), standard knitwear from India (to leverage cotton and lower cost), most bulk garment styles from Vietnam (balance of quality/cost), and simple T-shirts or bulk uniforms from Cambodia (lowest cost).

- Automotive and industrial components: India (and China) as primary choices. India’s automotive component industry is well-established (from engine parts to wiring harnesses), often at 20-30% lower cost than Western sourcing. China is also a key player especially for electronic components in vehicles. Vietnam and Cambodia play minor roles here (though Vietnam has some motorbike and electronics parts manufacturing).

- Pharmaceuticals, chemicals: India and China are the go-to sources. India’s pharma capability is world-class for generics and formulations, while China dominates in active pharmaceutical ingredients (APIs) and raw chemicals. Vietnam and Cambodia have minimal presence in pharma manufacturing at export scale.

- Consumer goods and appliances: A mix of China, Vietnam, India depending on the item. Small home appliances, for example, might be sourced from China (if high volume) or India (if cost-sensitive, and if Indian suppliers exist) with some simple assembly possibly done in Vietnam. Cambodia is generally not used here except for very simple assembly or as an add-on for tariff reasons.

To decide “who should make what”, continually evaluate the industry cluster and supplier base in each country. China has clusters for nearly every product (electronics in Shenzhen, toys in Shantou, textiles in Guangzhou, etc.).

Vietnam has strong clusters in apparel (e.g. Ho Chi Minh City for garments), electronics (Bac Ninh and surrounding northern provinces for tech hardware (source)), and furniture (Binh Duong province, etc.). India’s clusters include textiles in Tirupur or Surat, automotive in Pune/Chennai, and pharma in Hyderabad/Gujarat.

Cambodia’s clusters are mainly garment zones around Phnom Penh and Sihanoukville. Aligning with these clusters will get you better supplier options and infrastructure tailored to that industry.

Actionable Tips – Aligning Products with the Right Country:

- Map Country Strengths to Your BOM: Break down your bill of materials and identify which components or products could be made where. For each item, ask “Which country is known for this?” Use resources like industry reports or sourcing partners’ insights. For instance, if you need plastic injection molded parts, China or India may offer more suppliers; for cut-and-sew fabric items, Vietnam or Cambodia might be optimal.

- Use Multi-Country Production for One Product: Don’t be afraid to split production stages across countries. Many companies do this: e.g., fabricate metal components in China (for quality), source cables or textiles from India (for cost), then assemble the final product in Vietnam (for trade advantage and labor savings). This modular approach leverages each country’s best capability. Just ensure you account for the logistics and integration of these steps so the supply chain flows smoothly.

- Pilot New Categories in Emerging Hubs: If you’ve always made a product in China, try a pilot run in Vietnam or India, especially if the product is becoming more commoditized. You might find that Vietnamese or Indian factories, perhaps run by ex-China operators, can now handle it. For example, electronics manufacturing services (EMS) providers have set up in Vietnam; you could test manufacturing a subset of your devices there to see if quality and output meet requirements.

- Stay Updated on Industry Developments: The specialization landscape can shift. Vietnam’s push into high-tech manufacturing is accelerating, and India is investing in electronics and solar panel production. They signal future capability by keeping tabs on major investments (like a new semiconductor plant announcement or a large factory opening). An experienced sourcing firm (like EWB) can provide on-the-ground updates about which industries are taking off in each country, ensuring you tap into new opportunities early.

Quality Assurance and Scalability

No sourcing strategy is complete without ensuring consistent quality and the ability to scale production to meet demand. As companies diversify across China, Vietnam, India, and Cambodia, maintaining quality standards across all locations is both challenging and necessary. Each country’s manufacturing sector has different maturity levels, which impact quality control processes and scalability.

Quality Assurance Across Countries:

China

China’s manufacturing has matured to a point where you can find world-class quality, but you can also find corners cut at the low end. It’s a “double-edged sword” in China: top-tier suppliers deliver impeccable precision, while some low-cost vendors might skimp on QC (source). Over the decades, China has built a robust ecosystem of third-party inspection firms, testing labs, and certification agencies. If you need an ISO 9001 factory or a supplier certified to aerospace or automotive standards, China has many.

Vietnam

Vietnam has been rapidly improving in quality standards. Manufacturers there have invested in modern equipment and aligning with international standards (over 12,000 Vietnamese national standards, 60% now harmonized with international norms (source)).

It’s now common to see Vietnam factories with ISO certifications and compliance with global retailer audit protocols. Still, Vietnam is building its track record; for highly specialized industries (like medical or aerospace), Vietnam is catching up and may not have the depth of quality culture yet that China’s top suppliers do (source).

India

India presents a mixed picture: in sectors where it has long experience (textiles, pharma, auto parts), quality can be excellent – Indian suppliers are known for craftsmanship in textiles and rigorous standards in pharmaceuticals (source). Consistency can vary in newer sectors or highly mass-produced consumer goods, and extra monitoring is wise (source). English language ability in India can be an advantage for communicating quality requirements clearly, but on the factory floor, enforcement of standards might need frequent follow-up.

Cambodia

As an earlier-stage industrial player, Cambodia often requires the most hands-on quality management. Many Cambodian factories are overseen by foreign managers who bring in quality systems, but overall the country doesn’t yet have a widespread reputation for high precision. That said, Cambodian suppliers can meet quality expectations with proper training and auditing for straightforward products like basic apparel.

Scalability:

China

Another consideration is the capacity to ramp up production quickly. Here, China still holds a big advantage. Chinese manufacturers can often triple output on short notice, supported by their massive labor pools and supplier networks. Factories in China can number in the thousands or even tens of thousands of workers, enabling them to take on huge orders or last-minute surges.

India

India, with its enormous population, theoretically also has scalability. Still, constraints like infrastructure and labor organization mean ramping up can take longer (finding and training an extra 5,000 workers isn’t as turnkey in India as it can be in China’s industrial cities). However, India’s scale shines for long-term growth – you can set up multiple plants across different states to incrementally build a very large operation.

Vietnam

Vietnam’s population (~98 million) is much smaller than China or India, and while its workforce is growing, Vietnam will reach capacity limits in some industries. Indeed, some large manufacturers in Vietnam are already recruiting workers from more remote provinces or even automating due to labor supply tightness in main hubs.

Still, Vietnam has shown an ability to scale in certain sectors – e.g., the footwear and electronics industries each employ hundreds of thousands in Vietnam, with giants like Samsung employing over 100,000 Vietnamese across its factories.

The question is whether Vietnam could support multiple new large industries at once; its scaling is strong within its established sectors, but if you tried to suddenly manufacture 5 million cars there, it would be a stretch.

Cambodia

Cambodia has the smallest workforce of the four (~16 million population) and is still largely agrarian. Scaling in Cambodia is the most limited – you may find enough workers for one big factory per area, but the talent pool and infrastructure would strain beyond that. Companies using Cambodia often keep volumes at a moderate level and use it as part of a multi-country production strategy, rather than relying on Cambodia to deliver huge volumes alone.

Ensuring Quality When Diversifying:

A key challenge in multi-country sourcing is maintaining consistent quality control processes. It’s critical to establish unified standards and oversight. Many firms create a central quality manual and supplier guidelines that apply to all vendors, whether in Shenzhen, Ho Chi Minh City, or Bangalore. Regular audits and inspections are a must.

Data reflects this need: as U.S. brands explore new suppliers in places like Cambodia and Indonesia, their demand for third-party inspections and audits has surged (up 36–62% YoY) (source ). This implies that companies proactively send inspectors or hire firms to check product quality and compliance as they venture into less-proven regions.

For your strategy, plan for on-the-ground quality assurance in any new country you source from. It could be internal QC teams, third-party inspection agencies, or a sourcing partner’s local staff who perform in-process checks and final random inspections.

Additionally, consider small initial orders or trial runs with new suppliers/countries to gauge quality before scaling up. It’s easier to correct quality issues on a 5,000-unit pilot than a 500,000-unit main order. Use those trials to calibrate expectations and provide extensive feedback.

Over time, many suppliers in Vietnam or India can reach near-parity with your Chinese suppliers’ quality, but it may take a few production cycles and knowledge transfer. Encourage cross-learning: for instance, if your long-term Chinese supplier has perfected a process, see if they (or an engineer you hire) can train the new Vietnam factory’s staff. Some forward-thinking companies even send their China QC managers to new plants in Vietnam/India to instill the same quality discipline.

Maintaining scalability often ties back to multi-sourcing. If you foresee needing to scale beyond what one country can handle, set up parallel production lines in two countries. For example, you might plan that “during peak season, we’ll produce 70% of units in China and 30% in Vietnam to meet total demand” – this way, neither country’s capacity limitswill bottleneck your growth.

Also, build flexibility in contracts: suppliers with multiple facilities (like a big Chinese manufacturer that also opened a Vietnam plant) can offer scalability by shifting some work internally between their sites, if you’ve laid the groundwork in your agreements.

Actionable Tips – Ensuring Quality and Scale:

- Harmonize Quality Standards: Develop a single set of quality criteria and SOPs that all suppliers must follow, regardless of location. This includes material specifications, tolerances, testing methods, and packaging requirements. Share these documents and train each supplier’s QC team on them. Use the highest standard among your current suppliers as the benchmark for all.

- Invest in On-Site Inspections: Particularly when working with new countries or suppliers, don’t skimp on inspections. Schedule regular in-line and final inspections. Leverage third-party quality firms or your sourcing partner’s local experts (EWB, for example, offers in-country quality control services to verify production). Over time, as trust and consistency build, you can reduce the inspection frequency, but early vigilance is key.

- Start Small to Go Big: Validate quality on smaller orders before scaling up. For instance, before asking an Indian supplier for 100,000 units, maybe start with 10,000 units and do a full quality audit on that batch. Use the findings to implement corrective actions. Once they pass the smaller batch with high marks, increase the order size. This phased approach avoids large-scale quality failures.

- Plan Dual Capacity for Scaling: Don’t rely on a single factory or country to handle your maximum projected volume. Even if one location can handle 100% of your needs, build in a backup. Identify a secondary supplier (or an affiliate factory) in a different country that can produce say 20-30% if needed. This not only covers you if you suddenly need to ramp up, but also if your primary supplier has an outage. Having multi-country production running in parallel means you can scale output by simply shifting allocation, without starting from scratch.

- Continuous Improvement Programs: Encourage and assist suppliers in all countries to adopt continuous improvement and lean manufacturing techniques. This will boost both quality and productivity. Share best practices between suppliers in different countries (e.g. a kaizen from China supplier could help Indian supplier). As part of the partnership, EWB or your sourcing team can facilitate workshops or exchange visits to uplift the overall performance across your supply base.

Infrastructure, Policy Incentives, and Trade Access

The less visible, but equally crucial, part of sourcing strategy is evaluating the operating environment in each country. This includes physical infrastructure (ports, roads, electricity), government policy incentives for manufacturers, and trade agreements or tariffs that affect market access. These factors can significantly sway the total cost, reliability, and speed of your supply chain.

Infrastructure:

China

China’s infrastructure is often the gold standard in Asia. It has modern highways, extensive rail freight networks, some of the world’s busiest container ports (Shanghai, Shenzhen, Ningbo, etc.), and reliable power grids in industrial areas. This means materials and goods flow efficiently inside China and out, contributing to China’s shorter lead times for delivery (source). A container can be loaded at a factory and be on a vessel the same day thanks to streamlined logistics.

Vietnam

Vietnam has been investing heavily in infrastructure and boasts several high-quality ports like Cai Mep (near Ho Chi Minh City) and Hai Phong (near Hanoi), though its internal transport (trucking routes, rail) is still developing. Manufacturers in Vietnam’s key zones are generally near port or airport access, but congestion can occur as export volumes grow.

Power infrastructure is decent but was tested in 2023 when Vietnam faced rolling blackouts due to record heat and energy demand – a reminder to ensure backup generators or alternate plans for critical production.

India

India historically lags in infrastructure: ports such as Mumbai/JNPT and Chennai handle huge volumes but can suffer delays; roads can be slow, and inland logistics can add days to delivery times. The government is addressing this with projects like the Dedicated Freight Corridors (fast freight trains) and new highways. Still, when sourcing from India, expect potentially longer transit from factory to port and build that into lead times (source) (source).

Also, inter-state trucking in India might face checkpoints or bureaucratic slowdowns, though GST tax reforms have improved this somewhat.

Cambodia

Cambodia has limited infrastructure – one major deep-sea port (Sihanoukville), and a developing road network (a new expressway now links Phnom Penh to the port, built with foreign aid). Many goods from Cambodian factories actually ship via neighboring countries: e.g., trucked to Vietnam or Thailand ports for export, which can introduce logistical complexity. Infrastructure gaps can impact cost (higher trucking fees, longer transit) and reliability (e.g. if a key border crossing is backed up), making it essential to invest in efficient sortation systems that streamline warehouse operations and help offset external logistical inefficiencies. When considering Cambodia, factor in these extra logistics steps.

Policy Incentives:

Governments in all four countries offer various incentives to attract and retain manufacturers. These can include tax holidays, duty-free import of capital equipment, subsidies, or streamlined regulations in special economic zones (SEZs).

China

China had a big incentive push in earlier decades (SEZs like Shenzhen spearheaded manufacturing growth). Today, China’s policies are more targeted – for example, incentives for high-tech industries, electric vehicles, or semiconductor fabrication. While China may not offer many tax breaks for basic consumer goods anymore, local governments still sometimes give perks to major investors (like discounted land or utilities).

Vietnam

Vietnam actively incentivizes foreign direct investment: in many industrial parks, foreign manufacturers get corporate tax exemptions for the first few years and reduced rates thereafter, especially in high-tech or high-priority sectors. Vietnam’s stable governance and pro-business policies rank it high for ease of setting up factories.

India

India has launched ambitious schemes like the Production-Linked Incentive (PLI) programs in the last few years – these promised cash incentives to companies hitting manufacturing targets in sectors like electronics, pharmaceuticals, and solar panels. However, results have been mixed; by late 2024, only ~8% of the $23 billion allocated for these incentives had been paid out (source) (source), with many companies encountering bureaucratic hurdles.

The Indian government decided not to extend the initial PLI scheme broadly due to these challenges (source). Still, it is exploring more ways to support manufacturing (such as faster depreciation, single-window clearances, etc.). India can also offer state-level incentives for businesses – different states compete by offering subsidized land rates or electricity at lower industrial tariffs. Navigating these incentives might require local expertise, but the savings can be significant for large projects.

Cambodia

Cambodia offers incentives primarily through special economic zones and schemes for export industries: e.g., tax holidays for the first 9 years of a project, no import duties for raw materials for export production, etc. Additionally, Cambodia benefits from being part of ASEAN – so investors can tap regional treaties and relatively liberal investment rules.

One thing to watch with Cambodia (and to some extent Vietnam) is the stability of incentives: changes in international trade status (like the EU’s partial withdrawal of Cambodia’s EBA privileges (source)) or domestic policy shifts can alter the landscape. However, Cambodia continues to court investors, especially as it seeks to diversify beyond garments into areas like electronics assembly and agro-processing.

Trade Access:

Trade agreements and tariff regimes critically impact the landed cost of goods. Here’s a breakdown for each:

China:

As of 2025, China faces heightened tariffs in certain Western markets (especially the U.S., due to the ongoing trade tensions – many Chinese goods have a 7.5% to 25% additional tariff when entering the U.S.). China is a member of the Regional Comprehensive Economic Partnership (RCEP), which is a broad Asia-Pacific trade pact, but it does not have special free trade agreements with the US or EU aside from normal WTO terms.

This means exports from China to those markets typically face standard MFN tariffs and, in the case of the US, often the punitive tariffs. On the flip side, China’s inclusion in RCEP and its extensive network of suppliers mean if you assemble in China, you can import components from other Asian countries tariff-free or at low tariff, aiding cost if your supply chain is intra-Asia. But for exporting to Western markets, China might incur higher import duties compared to some neighbors.

Vietnam:

Vietnam is a trade agreement champion. It has secured around 17 free trade agreements by 2025 (source). Notably, Vietnam has an FTA with the European Union (the EVFTA), which is phasing out tariffs on Vietnamese exports to the EU. For example, many apparel and footwear items from Vietnam to the EU are enjoying reduced or zero tariffs, giving Vietnam a big edge over China or even Bangladesh for EU sourcing.

Vietnam is also in the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP), connecting it to markets like Japan, Canada, Australia with favorable terms. While Vietnam doesn’t have a direct FTA with the US, its normal trade relations status means it generally faces lower U.S. tariffs than China does under the trade war. However, one should stay alert: the U.S. has contemplated “reciprocal tariffs” on countries like Vietnam for trade imbalances (source ), so far largely speculative.

Overall, Vietnam’s broad trade network often means sourcing from Vietnam can reduce or eliminate import duties into key markets – a major cost advantage. This is one reason many Chinese companies have invested in Vietnam, to route products through Vietnam for better access to the West (source) (source).

India:

India’s trade agreements are relatively limited, as the country has taken a more protectionist stance in some trade talks. It notably opted out of RCEP, fearing an influx of imports. India has some trade deals (with countries like Japan and South Korea, an interim deal with Australia, and ongoing negotiations with the UK and EU), but as of 2025, there is no comprehensive FTA with the EU or US.

This means Indian exports to US/EU typically face standard tariffs (for many goods like apparel are significant, others like specific machinery are modest). On the positive side, India benefits from generalized tariff systems for developing countries to some extent, and importantly, India’s huge domestic market means many companies manufacture in India for Indians (so trade access is less an issue if your goal is to sell in India itself).

If your sourcing strategy includes selling into India, local production can bypass India’s often high import tariffs (India imposes high duties on products like electronics to encourage local production).

There’s a subtle advantage here: sourcing from India might also allow you to service the Indian market more easily under the same umbrella, which can be a strategic factor. Also, India’s membership in organizations like the South Asian Free Trade Area (SAFTA) is less impactful due to the smaller trade within the region.

Cambodia

Cambodia has enjoyed preferential trade schemes as one of the Least Developed Countries (LDCs). It was part of the EU’s Everything But Arms (EBA) initiative which gave duty-free access for nearly all EU exports until 2020 when the EU suspended that status for certain products over human rights concerns (source).

Even with that partial withdrawal, many Cambodian goods still enter the EU with lower tariffs than standard. Cambodia also has duty-free access to some other markets under GSP (Generalized System of Preferences) schemes. However, the U.S. does not include apparel in its GSP, so Cambodian garments to the U.S. pay normal tariffs.

Cambodia is in ASEAN and thus in RCEP, meaning it can trade regionally at low tariffs and also could potentially be a trans-shipment point (though rules of origin need to be met). In practice, Cambodia’s trade advantage is strongest for the EU and some developed markets excluding the U.S..

Businesses targeting EU markets might find Cambodia a cost-effective base for goods that would face higher tariffs elsewhere. However, these benefits depend on international policy (as seen with the EBA change).

In planning your strategy, calculate the landed cost with tariffs for each country option. Sometimes a product is cheaper ex-factory in one country but after tariffs and freight, another country is more competitive. For instance, a product sourced in China might incur 25% U.S. tariff, wiping out any savings; whereas sourcing it in Vietnam or India could avoid that tariff, even if the factory price is slightly higher.

Additionally, consider any non-tariff barriers or regulatory differences: different countries have different track records on compliance (e.g. meeting EU product standards, labor compliance which buyers might care about, etc.). Many firms also look at the political stability and business environment, Vietnam’s consistently pro-FDI policies or India’s democratic legal system might influence long-term comfort.

Actionable Tips – Navigating Infrastructure, Policy, and Trade:

- Include Logistics in Cost Calculations: When comparing quotes from different countries, add estimated inland transport costs and shipping times. For example, a supplier in inland India might require a 2-day truck to port and higher freight costs, whereas a Vietnam supplier near Hai Phong port could ship out in a few hours. Use this to adjust price comparisons. Sometimes, a slightly higher factory price in a well-located country ends up cheaper overall than a low price in a logistically challenged spot.

- Exploit Free Trade Agreements: Structure your sourcing to take maximum advantage of trade deals. If you serve the EU market, lean towards Vietnam or Cambodia for relevant products to benefit from lower tariffs (EVFTA or GSP advantages). If in Asia-Pacific, sourcing within RCEP countries (all four in discussion are RCEP members except India) can ease moving components around. Work with trade compliance experts to ensure you meet rules of origin to qualify for FTA tariff cuts.

- Investigate Incentive Zones: For larger sourcing projects or setting up your own manufacturing with a partner, investigate each country’s special economic zones or incentive programs. Vietnam’s industrial parks or India’s state schemes might offer tax breaks that indirectly lower your supplier’s costs (and thus your prices). Engage with local investment agencies or consultants. Often, EWB can help navigate these local incentives or connect you with suppliers operating in those zones to get better deals.

- Plan for Infrastructure Mitigation: In countries with weaker infrastructure, mitigate proactively. Build in extra lead time in your supply chain schedule for India or Cambodia shipments. Encourage suppliers to maintain buffer stocks of raw materials in case of port delays. If power outages are a risk (e.g., in parts of India or Vietnam during peak summer), discuss backup generators or alternate shift timings with your supplier. Such planning avoids nasty surprises and production downtime.

- Stay Current on Policy Changes: Government policies can change with little notice – a sudden export ban, a new import requirement, an increase in minimum wages, etc. Subscribe to news alerts or industry updates for the countries you source from. For example, if there are talks of the U.S. reviewing trade preferences or a new bilateral trade deal involving one of your sourcing countries, you’ll want to know. Being informed lets you pivot or advocate accordingly. Partners like EWB often provide clients with periodic updates on relevant policy shifts in Asia, acting as your eyes and ears on evolving conditions.

Conclusion: Crafting a High-Performance Asia Sourcing Strategy for 2025

In 2025, successful sourcing in Asia is about building a balanced, multi-country strategy—not picking one “best” location. China offers unmatched scale and supplier depth; Vietnam combines cost efficiency with trade access; India brings scale, government incentives, and a rising tech edge; Cambodia delivers ultra-low costs for labor-intensive goods. The most resilient supply chains will leverage these strengths together.

Your role is to align this diversity with your business goals. That might mean keeping China for complex or high-volume production, scaling in Vietnam for mainstream goods, piloting new lines in India, and using Cambodia for cost-sensitive SKUs. There’s no one-size-fits-all formula—but every country in your sourcing mix should serve a clear purpose: reducing cost, managing risk, improving quality, or entering new markets.

Execution is just as critical as strategy. Managing multiple suppliers across countries requires local insight, operational discipline, and strong partnerships. That’s where experienced partners like East West Basics (EWB) can add real value—handling supplier identification, audits, production oversight, and quality control across Asia. With local teams in China, Vietnam, India, and Cambodia, EWB simplifies complexity so you can focus on growth.

Ultimately, a well-structured, diversified Asia sourcing strategy gives you agility, resilience, and control—the capabilities needed to thrive amid global uncertainty. The companies acting to build these networks won’t just survive disruption—they’ll outperform competitors. In today’s market, supply chain strategy is a business strategy, and Asia remains your most powerful lever